The quest for electrification of goods traffic among other things has caused establishing of several test routes with overhead wire for heavy trucks. However, not the whole industry views this as the best way to make truck transport more ecologically friendly.

In Germany alone, three test routes on public roads are equipped with overhead wire: A section of the Autobahn Lübeck-Hamburg close to Lübeck, a section of Autobahn south of Frankfurt, and a section of federal highway („Bundesstraße“) in the Black Forest. All three sections are in lo-cations that serve lots of regional goods traffic, so that the few kilometers of overhead wire cover a somewhat significant portion of at least some truck routes. A similar concept is behind the electrification of a route near Los Angeles in the US. For the time being, each line will operate with just a few test trucks. The line near Frankfurt is already open. The technology is described by a Siemens statement:

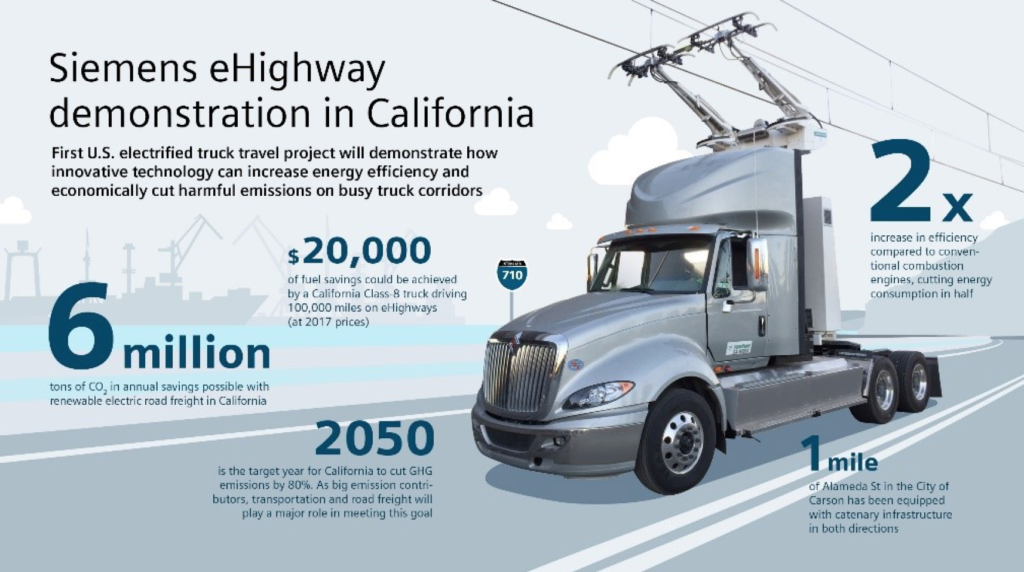

“Siemens and the ‘South Coast Air Quality Management District (SCAQMD)’ are running a one-mile, zero-emission eHighway demonstra-tion in the Californian city of Carson, U.S., near the ports of Los Angeles and Long Beach. Three trucks hauling freight are running along the stretch of highway which uses Siemens technology to electrify select highway lanes via an overhead catenary system. This catenary system supplies the trucks with electric power, similar to how modern-day trolleys or street-cars are powered on many city streets. The system also allows for truck operation outside of the electrified sections of infrastructure.”

The key is the newly developed actively moveable pantograph: “This ena-bles automatic connection to/disconnection from the overhead contact line at speeds of up to 90 km/h and also automatic compensation of all vehicle movements within the electrified lane. Depending on the opera-tion mode, the pantographs can be raised or lowered automatically or even manually at the touch of a button and enable full vehicle flexibility in comparison with trolley buses or hybrid trucks in open-cast mining.”

However, the industry is not united in the drive towards overhead wire. Daimler, while taking part in the test, quite openly favours battery driven trucks. The company concludes that it would be easier to install charging facilities and increase the range of battery-powered trucks. A manager is quoted saying: “There already is an efficient goods transportation system under overhead wire: Deutsche Bahn.” (Die Welt, 15.4.19) Daimler appar-ently sees the overhead wire as a costly long-term investment that may take many years before it is ready to carry significant volumes of freight.

The same article of Die Welt also explains an important reason behind the hesitation of Daimler in its role as a large truck manufacturer: Manufac-turers need quick fixes to lower the CO2 emissions of their fleet. Overhead wires simply will not be available on time to meet this demand. Manufac-turers therefore are more inclined to go for solutions that may limit the range of the truck but that can be implemented immediately.